Premium, Long-Lasting Reflective Insulation Technology

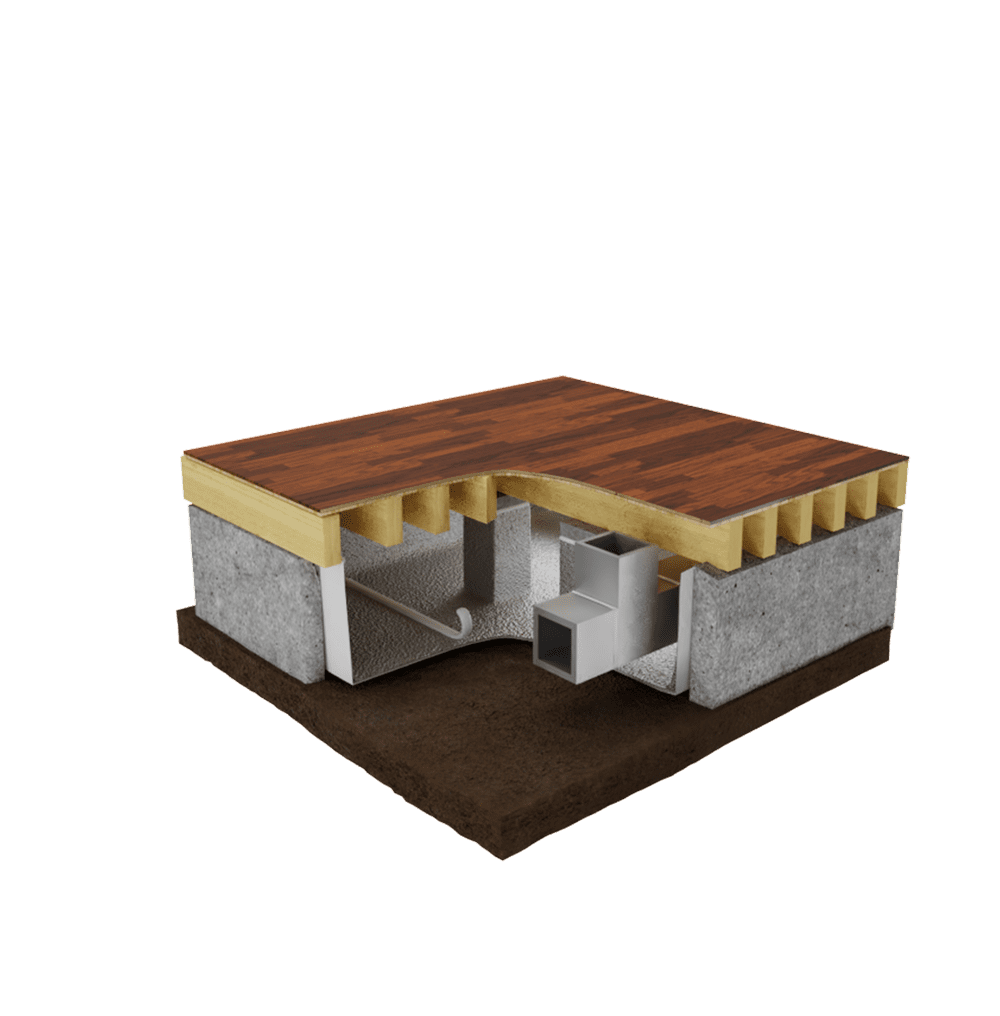

As a builder and insulation specialist, protecting your crawl spaces becomes paramount, and that is exactly where RBI Shield™ comes in handy. Envision enveloping your structures in a technologically advanced shield that maintains a warm ambiance in the winter and ensures a cool refuge during the summer months.

This is the effectiveness of RBI Shield™, crafted with exceptional R-value and low-e reflective surfaces, specifically engineered to optimize thermal performance across crawl spaces and beyond. It’s not merely an insulation solution; it is a strategic ally meticulously designed to enhance your project’s thermal integrity and energy efficiency, ensuring a robust safeguard against the elements.

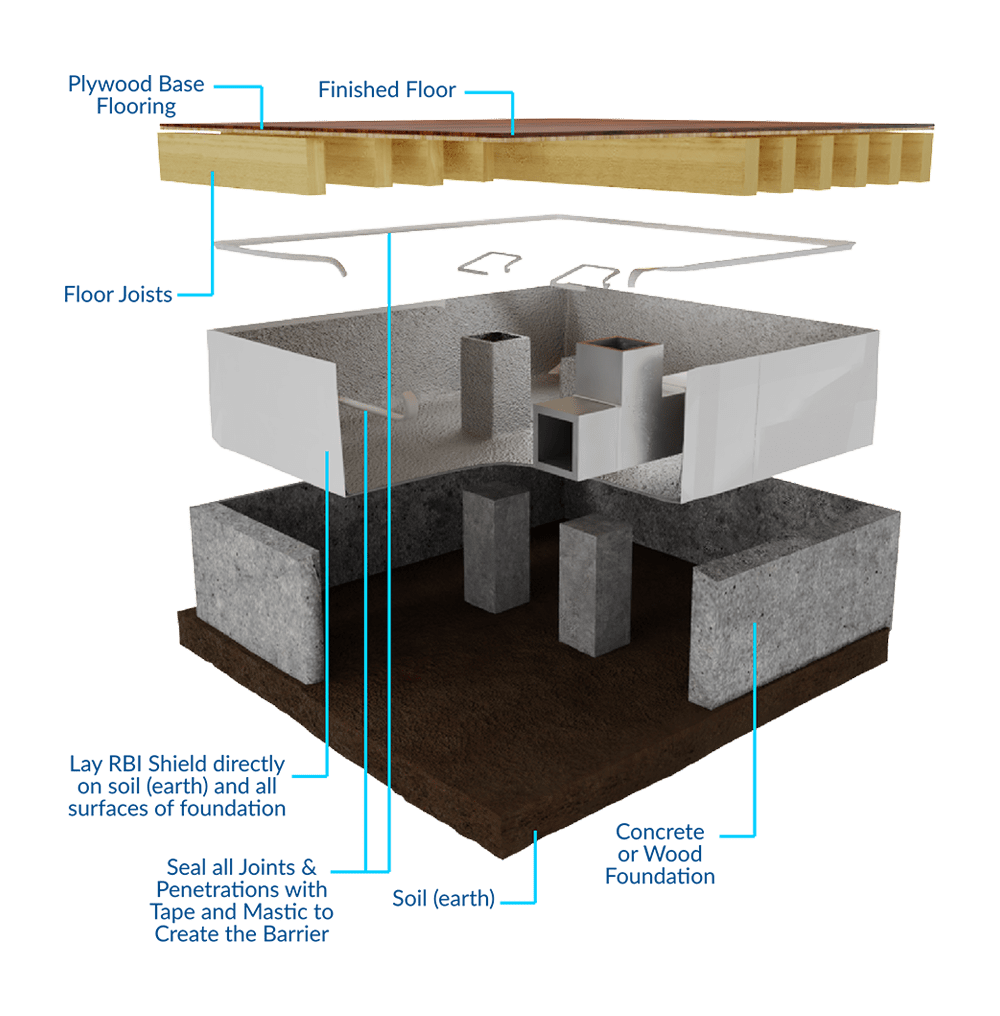

Precision-Engineered with Vapor Barrier Capabilities

RBI Shield™ goes beyond traditional insulation by serving as an effective vapor barrier when all joints are sealed meticulously. This feature mitigates condensation risks, safeguarding the structural integrity of buildings and ensuring the longevity of your projects

Formulated for Durability and Longevity

Infused with UV inhibitors and antioxidants, RBI Shield™ is formulated to resist delamination and degradation, ensuring that it maintains not only its thermal performance but also its structural integrity over time, even under rigorous conditions.

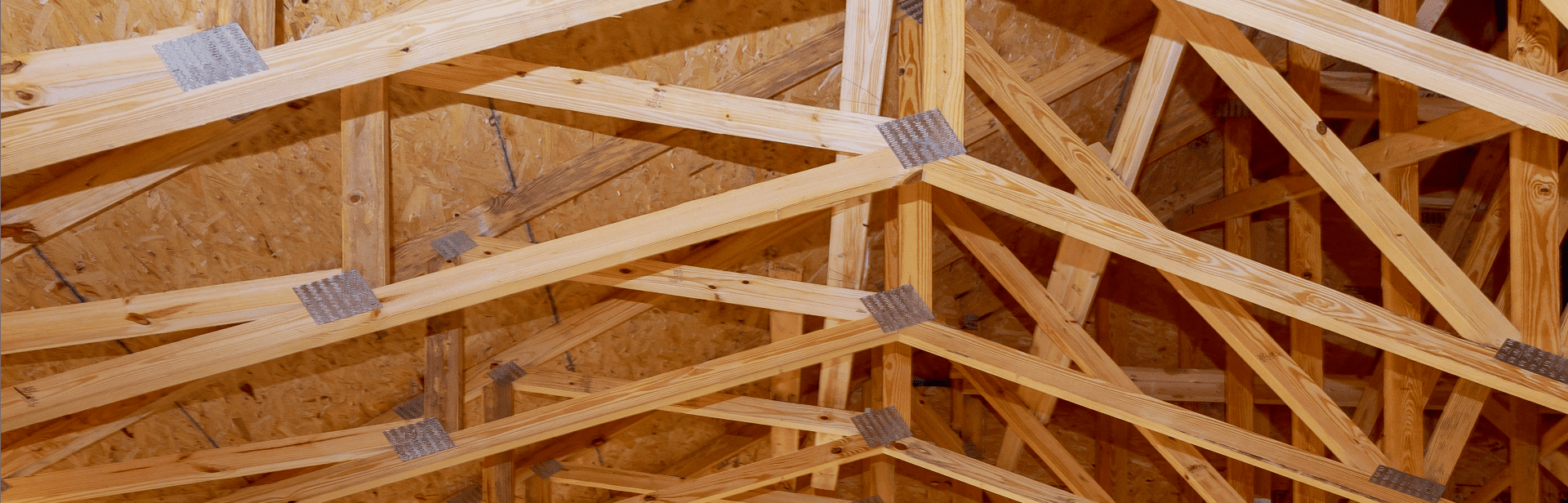

Versatile and Easy Installation Process

Available in a wide selection of widths, in single and double bubble versions, RBI Shield™ is designed to cater to a diverse range of architectural needs, giving you a high-performance insulation solution for every project

With its flexibility, RBI can easily be cut and conformed to various structures and existing equipment. This reduces your labor time and costs, enhancing your projects efficiency and profitability.

Key Benefits & Innovative Features for Your Build

- Flexible, Multi-Use Reflective Bubble Insulation

- Single or Double Bubble Versions

- Seven (7) Sizes Available to Fit a Wide Range of Applications

- 16″, 24″, 48″, 54″, 66″, 72″, 96″ widths available

- Moisture Resistant Material

- Contains Anti-Oxidants that Reduce Impact of UV Radiation and Oxidation

- Ideal for New or Retrofit Applications

- Residential, Commercial, Industrial Buildings

- Ideal Applications include: HVAC Ducts, Crawl Spaces, Garage Doors, Metal & Post Frame Buildings

- White-Reflective version Doubles as a Clean, Finished Ceiling

- White-Reflective version Brightens Workspace

- Integral Tape Tab Option to Seal Seams

- Can be Used Alone, Back-Loaded or Combined with Mass Insulation

- Reduces Thermal Bridging for Continuous Insulation

- Class A Flammability Rating, Reflective-Reflective option

- Reduces Heat Loss in the Winter

- Improves Thermal Performance & Comfort Year-Round

- Lightweight and Easy to Install in New and Retrofit Applications

- Saves Energy to Reduce Operating Costs

- Installer-Friendly, No Itchy Fibers

- Ideal for Commercial, Agricultural or Institutional Applications

- Reduces Condensation

- Can be Used Alone or Back-Loaded with Mass Insulation

- Less Expensive than Spray Foam

- Meets Requirements for Projects Demanding Class A Flammability

- Integral Tape Tab Options for Aesthetically Finished Look

- National Network of Insulation Distributors and Contractors

| Width of Roll | Coverage sq. ft. | |||

| 16″ | 166 | |||

| 24″ | 250 | |||

| 48″ | 500 | |||

| 54″ | 563 | |||

| 66″ | 688 | |||

| 72″ | 750 | |||

| 96″ | 1000 |

| Test Method | Description | Results |

|---|---|---|

| ASTM E-96 | Water Vapor Permeance | 0 |

| ASTM D-3310 | Corrosiveness | No Evidence of Cracking or Pitting |

| ASTM C-1224-03, Section 9.5.2.4 | Pliability | No Evidence of Cracking or Pitting |

| ASTM C-1224-03, Section 9.5.1.4 | Bleeding & Delamination | No Evidencce of Bleeding or Delamination |

| ASTM E408-71 (2002) | Thermal Performance Emissivity | 0.03 |

| Reflectivity | 97% | |

| Service Temperature | 50 degrees F to 180 degrees F | |

| ASTM E-84 / 2599 | Flammability | Class A |

| ASTM C-1338 | Mold & Mildew | Pass |

| Reflective / Reflective | Flame Spread | Single Bubble: 0 Double Bubble: 0 |

| Smoke Development | Single Bubble: < 50 Double Bubble: < 50 |

|

| Reflective / Poly | Flame Spread | Single Bubble: 0 Double Bubble: 0 |

| Smoke Development | Single Bubble: < 50 Double Bubble: < 50 |

|

| ASTM D 638-01 | Tensile Strength MD | Single Bubble: 33.0 lb/in Double Bubble: 38.9 lb/in |

| Tensile Strength TD | Single Bubble: 21.4 lb/in Double Bubble: 27.6 lb/in |

|

| Tear Strength MD | Single Bubble: 2.6 lbf Double Bubble: 6.9 lbf |

|

| Tear Strength TD | Single Bubble: 3.2 lbf Double Bubble: 7.3 lbf |

|

| Compression Strength | Single Bubble: 57.3 lbf Double Bubble: 279 lbf |

- Meets ASTM C-1224-03 STANDARD SPECIFICATION OF REFLECTIVE INSULATION

- Meets International Building, Residential and Energy Codes

- Meets Florida Building, Residential and Energy Conservation Codes

- Meets ASTM C 1224, Reflective Insulation

TECHNICAL DOCUMENTS

FREQUENTLY ASKED QUESTIONS

IDEAL ADDITIONAL BUILDING APPLICATIONS FOR REFLECTIVE INSULATION

Request Product Support

Please don’t hesitate to reach out for inquiries, project consultations, or more information about FI-FOIL® reflective insulation system solutions. Our team of experts is dedicated to providing personalized assistance and technical expertise to meet your specific needs. Please note that the more completely the fields below are filled out, the more accurate your response will be.

A TRUSTED LEADER FOR REFLECTIVE INSULATION TECHNOLOGIES

PROVIDING YOU WITH SERVICE, INTEGRITY AND INNOVATION

We manufacture, market, and distribute high-performance reflective insulation technology and radiant barriers. Our products are sustainable and improve building performance and comfort all year round. Our reflective insulation technology is one of the fastest-growing technologies in the world and we want you to grow with us.