FI-FOIL® is offering a timely fix to the insulation shortage with the HY-Fi® hybrid system. HY-Fi® is easy to handle and a proven reflective insulation with low-e surfaces that enhance air space in cavities. The result is a way to save labor and significantly reduce radiant heat flow for a more efficient building envelope.

To illustrate why HY-Fi® is a growing solution to improve energy efficiency, we recall the simple physics of heat flow. Three forms of heat flow affect the building envelope—convection (fluid air movement), conduction (transfer by surface) and radiation (transfer by electromagnetic waves). While most mass insulations effectively reduce convection and conduction, they don’t substantially address radiation. (see Figure A, Insulation Types and Heat Flow Comparisons) Many contractors are now choosing hybrid systems that can address all three forms of heat flow in order to improve comfort and lower Home Energy Rating System (HERS®) scores.

Figure A

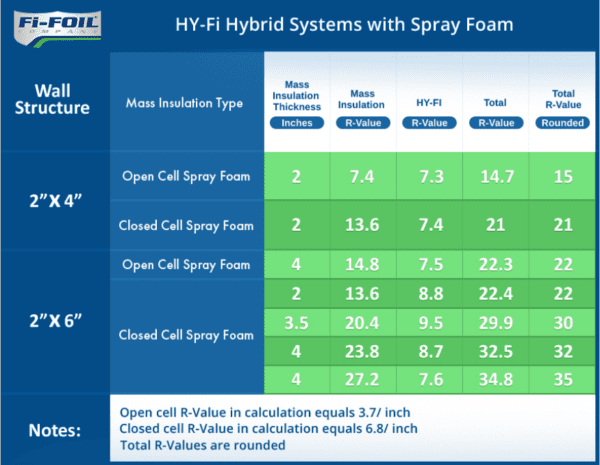

One growing solution, the Fi-Foil HY-Fi hybrid system, is commonly combined with spray foam. The resulting system effectively reduces all forms of heat flow with three high-reflectance surfaces that enhance the enclosed air space and work in conjunction with spray foam to improve thermal performance. When used together with spray foam, HY-Fi adds at least R7 to the wall system. Some examples include:

- 1

2-by-6-foot cavity filled with 4 inches of open-cell spray foam combined with HY-Fi® achieves R-22.

- 22-by-4-foot cavity filled with 2 inches of closed-cell spray foam combined with HY-Fi® achieves R-21.

In both cases HY-Fi® is installed on frame with reflective surfaces facing the foam and at least 1.5 inches of cavity air space. Not only is this a high-performance wall system, it also offers a clean, finished look for the wall, a cleaner job site and a speedier spray foam process. (see Figure B, HY-Fi® Hybrid Systems with Spray Foam)

Figure B

Using HY-Fi® hybrid systems can help contractors deal with the insulation shortage and provide better performance than blown-in fiberglass. The R-value of fiberglass alone is substantially lower than the R-value of hybrids containing low-emittance, high-reflectance barriers. In fact, a HY-Fi® system was specified in the National Association of Home Builders (NAHB) 2017 and 2018 New American Homes. This is a notable endorsement that using HY-Fi is effective to help maximize energy efficiency for those looking to lower HERS® scores and meet criteria for Net Zero homes.

The HY-Fi® system also works with other types of mass insulation to gain an additional R-7 for the wall system. For instance, HY-Fi® used with mineral wool batts will result in increased comfort, effective soundproofing and higher performance. HY-Fi® with cotton batts typically made of recycled materials is a good choice for those seeking a more natural insulation option. Using fiberglass batt with HY-Fi® is the most cost-effective hybrid solution for exceeding minimum requirements and providing support to keep batts in place for better long-term energy efficiency.

The shortage of blown-in fiberglass can be viewed as a setback or an opportunity. We at FI-FOIL® see it as an opportunity because HY-Fi® hybrid insulation systems can help save labor, reduce costs and improve performance. A HY-Fi® hybrid can increase the R-value of wall systems and is quickly becoming the preferred method of insulation.

For more information about HY-Fi®, visit the product page.