Air within the envelope of a building is subject to air infiltration, exfiltration and the three modes of heat transfer: conduction, convection and radiation.

Insulating materials address heat transfer through all three modes; however, the benefits can be lost, sometimes completely, if air infiltrates the envelope. Combined with other classes of insulation, such as spray foam, batt and rigid board insulation, air barriers can provide a solution—plus additional thermal performance (R-value) for homes and commercial buildings when installed facing an enclosed air cavity and/or air film.

Additionally, the aluminum and polyethylene components used in many air barriers act as vapor retarders. The combined effect reduces heat transfer and moisture within the building envelope.

Now with advanced technology in vapor transmitting air barriers, exposed walls are able to dry when needed to reduce risk of moisture accumulation.

Why Air Barriers?

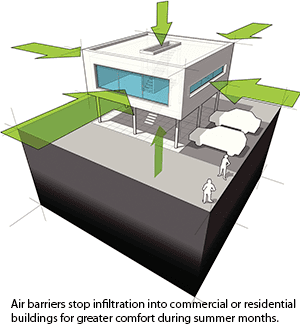

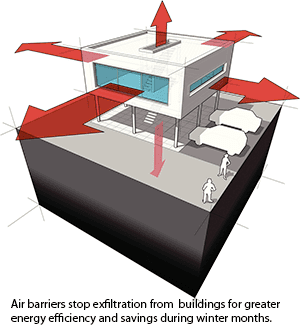

Air can infiltrate or exfiltrate through all sorts of building materials. In humid regions, for example, a sealed building protects temperature-controlled air indoors while keeping hot, moist air outside where it belongs. In colder climates, an airtight strategy protects the building envelope from condensation. In both cases, an air barrier significantly improves thermal performance for greater efficiency and comfort.

“Airflow can carry moisture that impacts a material’s long-term performance (serviceability) and structural integrity (durability),” Building Science Corporation says in “BSD-104: Understanding Air Barriers.” “Airflow also affects building behavior in a fire (spread of smoke and other toxic gases, supply of oxygen), indoor air quality (distribution of pollutants and location of microbial reservoirs) and thermal energy use. One of the key strategies in the control of airflow is the use of air barriers.”

Quality air barriers are designed to seal an entire building envelope, allowing no passage of air into or out of the building save for air conditioning systems and the voluntary opening of doors and windows.

The complete seal is hugely beneficial in climates with cold winters because it keeps heated air inside living areas. But that doesn’t mean that hot, humid or arid climates don’t also benefit. The same seal keeps cool conditioned air indoors to give occupants in hotter climates relief from the heat.

Air barriers are typically used like a building wrap, enclosing the walls and ceilings of residential and commercial buildings just inside the interior drywall. But other uses go even further toward sealing enclosed living spaces.

The Montana Energy Code Compliance Best Practices Tech Sheet notes that air and thermal barriers also come in handy for:

- Attics and attic accesses

- Piping and ducts

- Drop ceilings and soffits

- Staircase framing

- Porch roofs

- Flue and chimney shafts

- Recessed lighting

- Whole-house fans

- Windows and doors

- Floors

- Foundations

Contemporary Building Science and Codes

If a theme could be assigned to modern construction practices and standards, it would be energy efficiency. Heating, ventilation and air conditioning (HVAC) equipment and appliances aim to improve the comfort level and quality of indoor air and require a significant amount of electricity or gas to operate. Today’s construction guidelines and regulations attempt to reduce such energy usage by improving thermal insulation.

Air and thermal barriers that meet or exceed the standards set by the U.S. government-backed Energy Star® certification agency must first abide by the guidelines set forth in Energy Star’s Thermal Bypass Checklist Guide.

According to the guide, sealed air barriers are required on all six sides of a building’s insulated spaces: top, bottom, back, front, left and right.

In “Air Barriers Are Essential for a Modern, High-Performance Home,” FineHomeBuilding.com suggests a simple but effective trick to ensure that the finished structure will have a contiguous and continuous air barrier over the entire building envelope. When reviewing building plans, contractors should be able to trace an air barrier around the perimeter without lifting their pencil off the blueprint.

Installed air barriers must comply with a variety of building standards, such as the Air Barrier Association of America’s (ABAA) Code Requirements. ABAA’s standards include international building, energy conservation, residential and green construction guidelines and cover air barrier design, installation, materials, assemblies and testing. Other state and local codes may apply to air and thermal barriers used in construction. Builders are responsible for researching all codes for their locale.

Finally, ABAA offers training courses and certification programs for air barrier installers and auditors. Topics range from determining substrate conditions to ensuring continuity over joints and junctions, and accurate documentation for reporting. Continuing education is also offered after certification.

The FI-FOIL® Solution

SkyFlex™ Flexible Sheet Air Barriers are designed for all climates, made with materials suitable to protect the building envelope while improving comfort and efficiency. The low-emittance surfaces of SkyFlex™ resist radiant heat transfer to keep buildings cooler in the Summer and warmer in the Winter.

For more information on FI-FOIL®’s SkyFlex Air and Vapor Barrier or any of FI-FOIL®’s other products and services, such as Silver Shield™, HY-Fi®, Retroshield® and accessories, contact FI-FOIL® today at our website or call 888-513-4972.